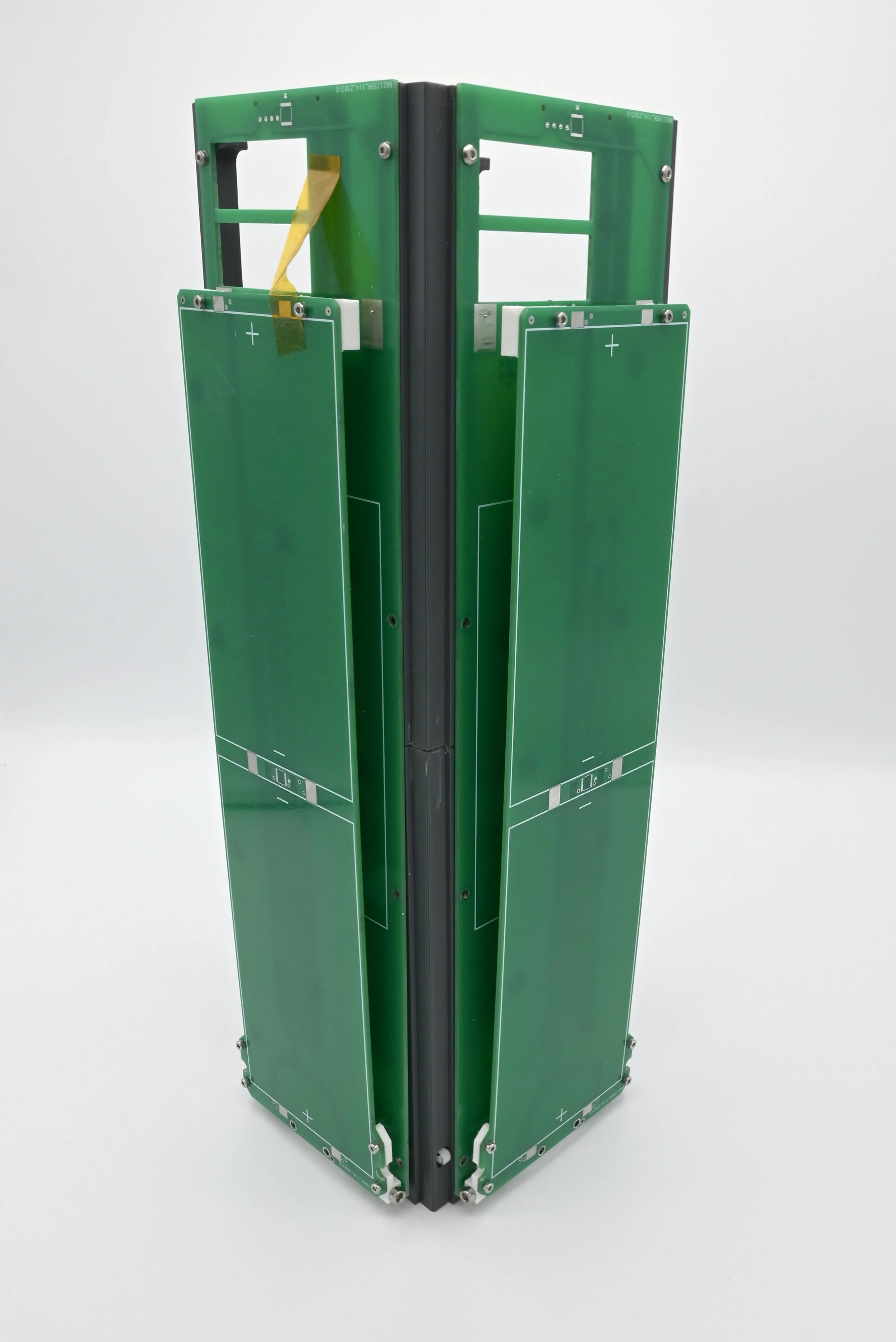

Mechanical Model

August 28, 2025

Author: Spencer Titcomb VA7YST

We are happy to announce the completion of our first 3D printed mechanical model of MARMOTSat. This marks an important milestone in validating the chassis design before moving into manufacturing, which is a time consuming process.

The model was printed in-house using our Bambu Lab X1-Carbon 3D printer. While it is not flight hardware, the mock-up provides a low-cost and practical way to verify mechanical compatibility between subsystems, or their models representing their mechanical envelopes, if they are not available yet. It allows us to confirm that fasteners, PCBs, and mounting features fit as intended while also helping us avoid tolerance stack-ups that could otherwise cause issues later in the project.

During assembly, the team evaluated all critical mechanical interfaces, including solar panel mounts, and internal board stacking. This process revealed a few small refinements that, if left unnoticed, could have caused significant delays, as turnaround on our machined structure can take up to ten weeks. With this practical check complete, the chassis design is rapidly approaching the manufacturing stage—a major transition as we move closer to building and integrating flight-ready hardware.

Beyond technical validation, this mechanical model also serves as a training and outreach tool. It helps new UVSD members and the broader community visualize the MARMOTSat project, while also supporting the team in developing assembly procedures that will be used for the flight model. Stay tuned for more updates on the chassis, we will be posting again once machining is complete!