TTC Heatsink Machining

July 16, 2025

Author: Spencer Titcomb VA7YST

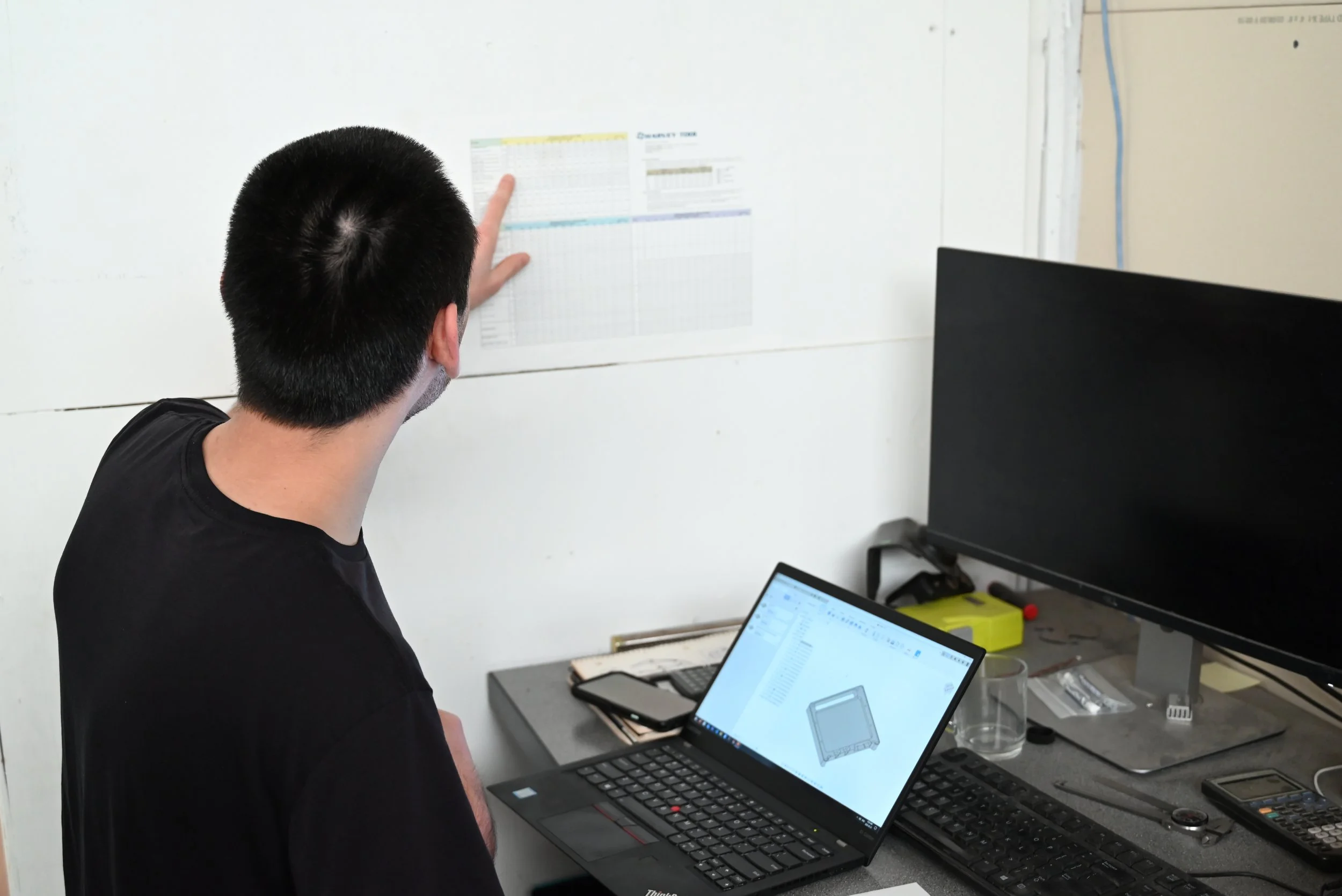

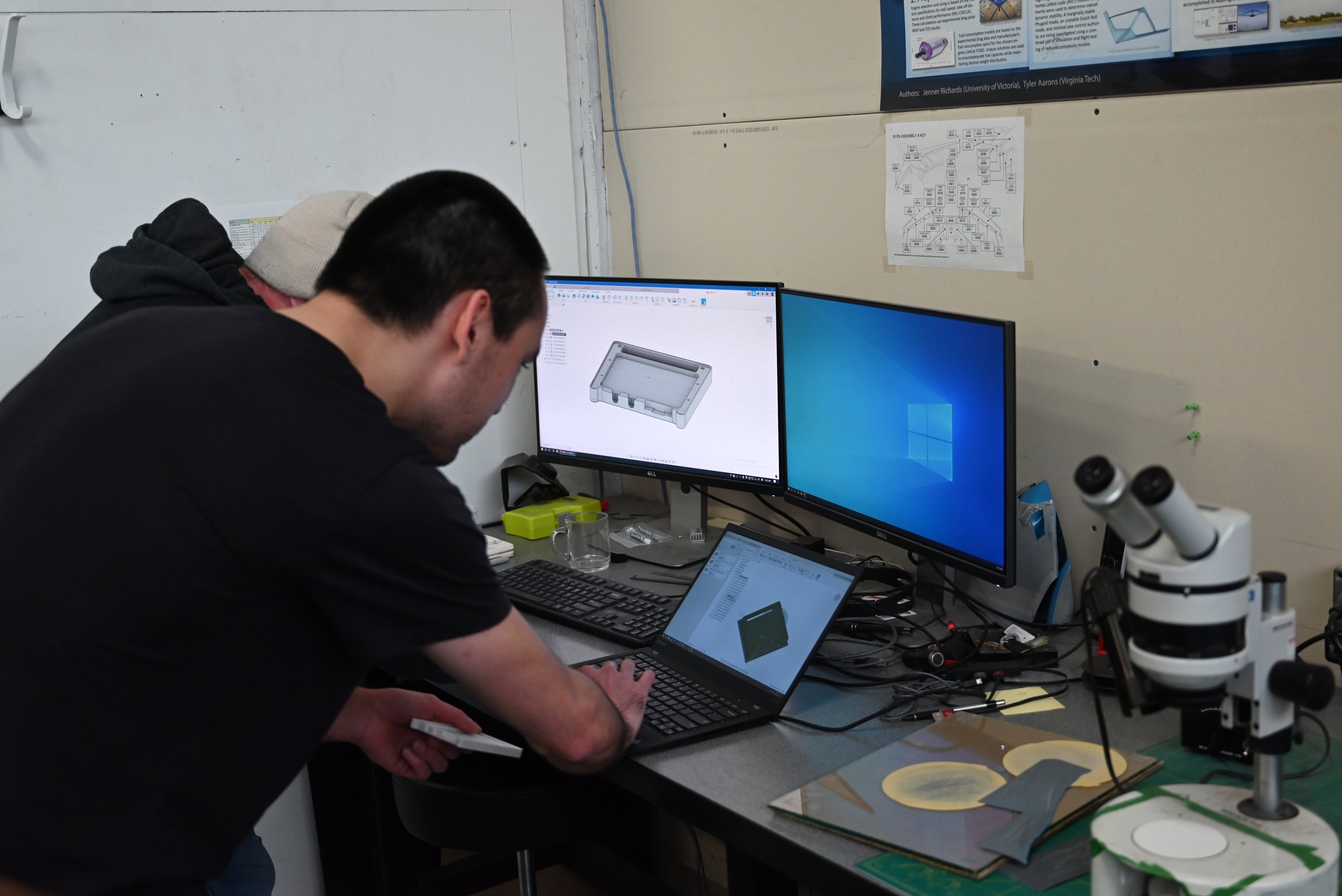

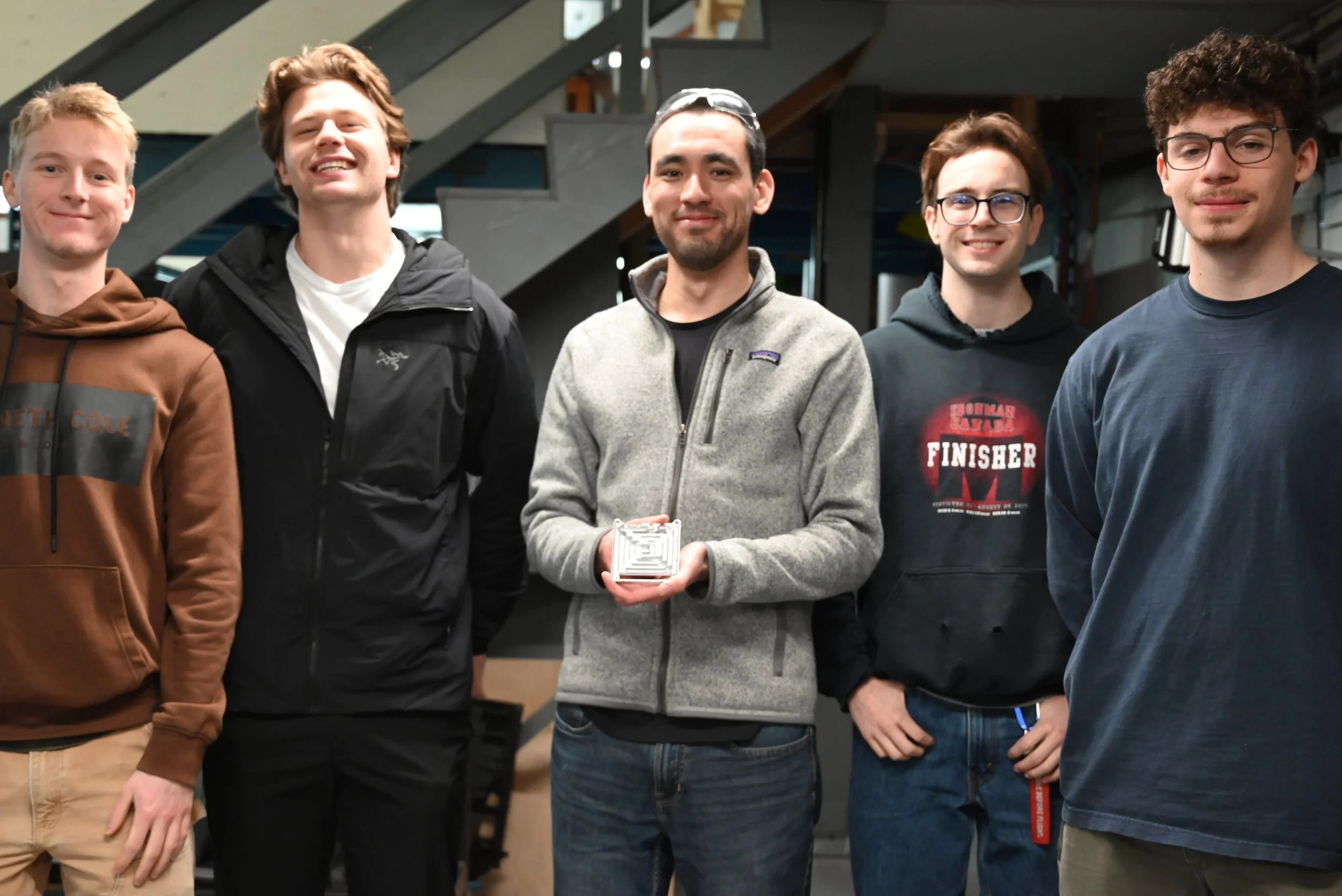

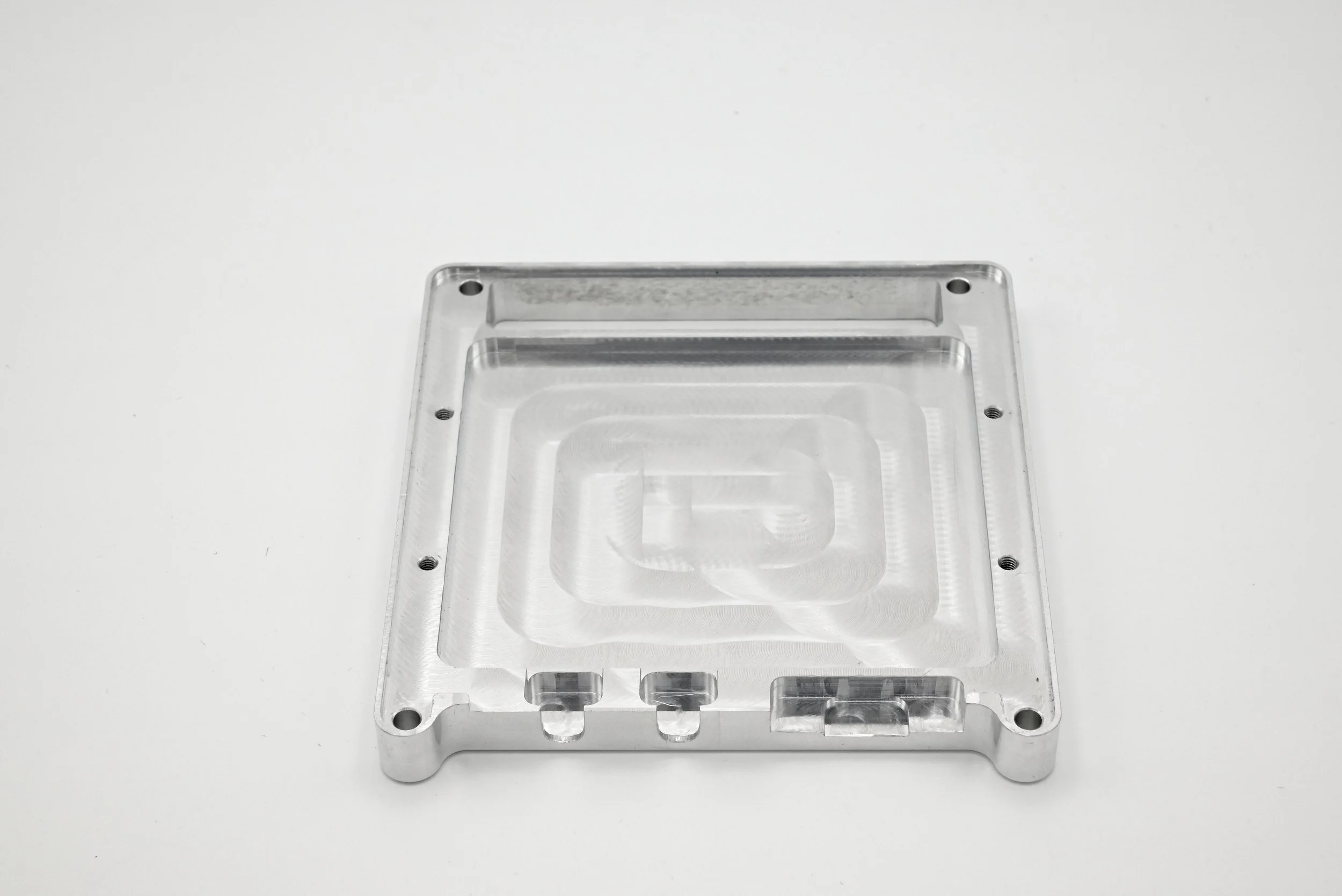

The team has successfully completed the in-house machining of a custom TT&C (Telemetry, Tracking & Command) heatsink for MARMOTSat—a crucial piece of hardware, shown below, that regulates thermal conductivity paths between the subsystem PCB and the spacecraft chassis.

The TT&C board is responsible for handling radio communications between MARMOTSat and its ground station at the University of Victoria. Given its high DC power draw during RF transmissions, and the lack of convective heating in the vacuum of space, managing this thermal load is vital to prevent irreversible damage. This heatsink is in direct contact with the board, providing a passive pathway to radiate heat away from the TT&C components. The part was machined entirely in-house using CfAR’s machine shop facilities in Sidney. A single Tormach 770MX CNC mill was used to complete most of the work, with hand tools used to clean up edges and finish details. The result is a precise, well-fitting component that integrates seamlessly with the TT&C board. Beyond just producing the part, this session served as an introduction to machining for several UVSD members. Tristan led the effort, walking students through the machining process, safety protocols, and basic shop operations—making it both a technical success and a valuable learning opportunity for the team.